Laser Cutting Solutions take your Projects to a whole new level with laser and Plasma Cutting Services!

Introducing laser cutting solutions where we offer top-of-the-line precision plasma cutting services that can take your projects to the next level.

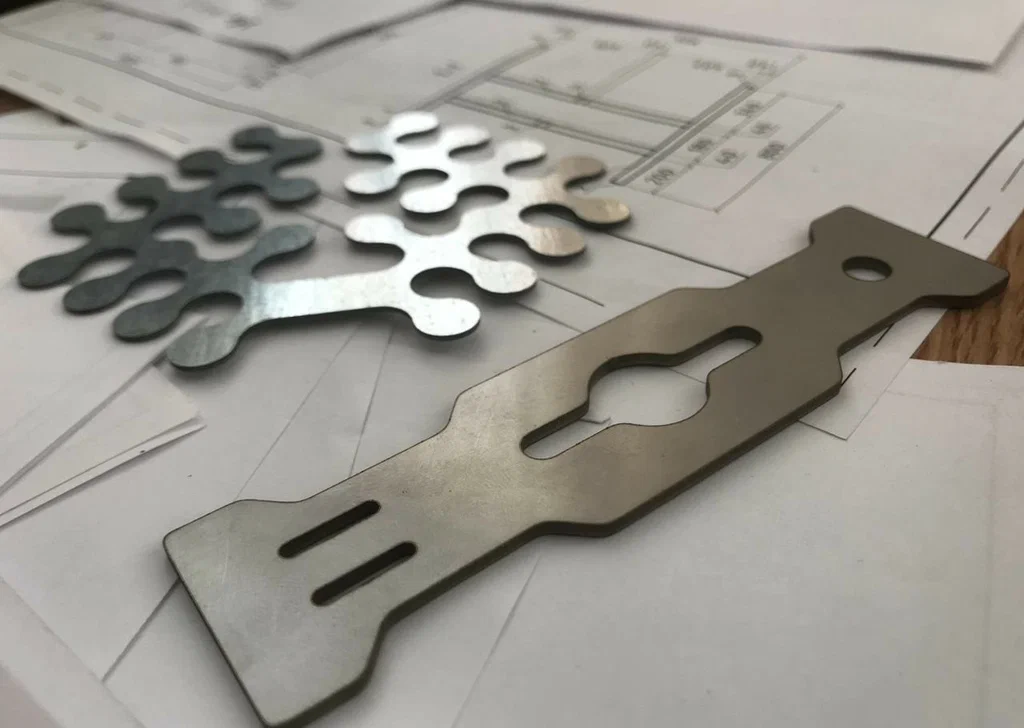

Our expert team is dedicated to providing high-quality cutting services for contractors looking to enhance their work. Whether you are in need of custom pedestrian gates, entry doors, railings, oversized panels, or unique architectural elements, our advanced C-N-C plasma cutting technology guarantees flawless results with every cut.

Mainly four types of lasers are used for cutting: CO2, fiber, neodymium (Nd) and Nd:YAG lasers. CO2 lasers are the most common due to their high energy and efficiency. CO2 lasers are suitable for engraving and cutting.

We mainly use fiber laser cutters as they offer several advantages over other types of laser cutters, such as higher speed, higher precision, and lower power consumption. Additionally, fiber lasers are much more durable and require less maintenance than other types of laser cutters. Fiber lasers also generate less heat during the cutting process, eliminating the need for cooling systems. These factors and benefits make them ideal for custom machining as they are accurate, reliable and cost-effective for the machine shop, resulting in lower manufacturing costs for part designers and engineers.

Among the many benefits of a high-power CNC laser cutting service are flexibility and precision, cost-effectiveness, and excellent quality. Laser metal cutting offers faster processing times and precision, although it is more difficult to cut thicker materials, which may be better suited for waterjet cutting. Furthermore, many industries such as tool machining, electronics, automotive, and aerospace use laser cutting service for various purposes. Here are some of the benefits a laser machine can provide:

The laser cutter produces a focused laser beam that allows precise cutting at high speed and minimal costs.

Considering that there is no tool positioned against the workpiece, the drilling speed depends only on the movement of the optical system.

Compared with conventional drilling, laser engraving and cutting have no contact with the surface. Over time, drilling bits can become dull, making the machining process slow and less productive. The heat produced by the drill bit can distort the material and change its mechanical properties.

The laser machine can cut a wide range of difficult materials, including steel and titanium superalloys. The laser cutting service includes cutting metal, ceramics, wood and some plastics.

Even a high-quality laser cutting service tends to develop some burrs when the machine finishes the cut.

Since the assist gas removes most of the molten material, minimal residual stresses are created along the edges. This results in a mechanically stable and clean cut.

Laser cutting metal is fast and efficient, making it one of the most cost-effective processes.

Contáctenos